Source factory

Heavy-Gauge thermoforming Manufacturer

- All-in-one thermoforming solution — CNC trimming, drilling and secondary finishing included.

- Short Lead Times for Prototyping & Production

- Low MOQ for Customization

- Fast Response

ForTOP Delivers Complete Heavy-Gauge Thermoforming Solutions — From Concept to Production — Backed by Over 24 Years of Expertise.

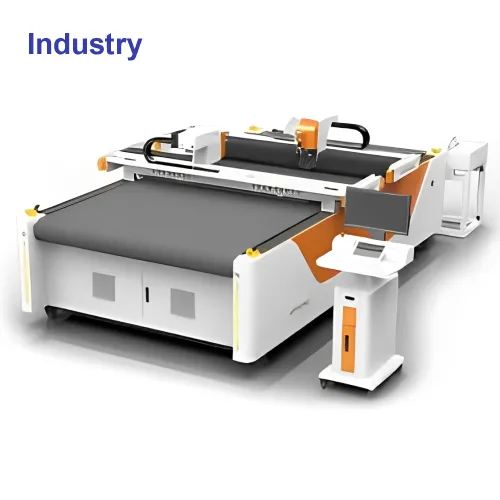

ForTOP Has Several Production Lines, a Tooling Shop, 3-Axis & 5-Axis CNC Machining Centers, and Multiple Thermoforming Production Lines.

A Dedicated Engineer Will Work With You at Every Stage — From Communication and Order Confirmation to Manufacturing and After-Sales Support.

Heavy Gauge Thermoforming

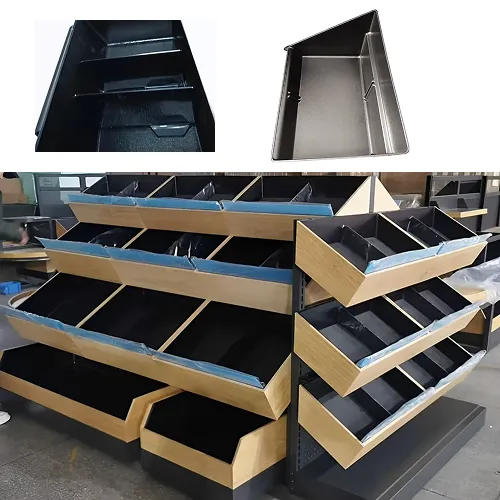

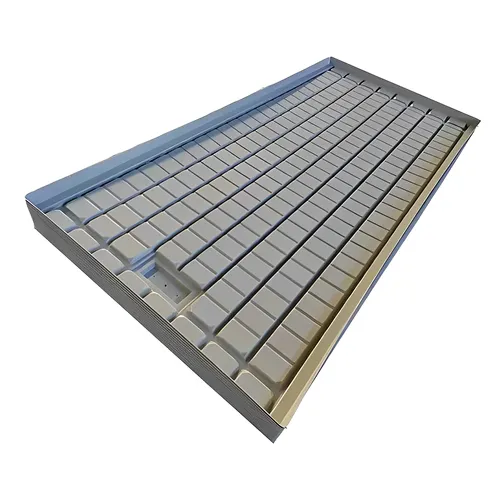

ForTOP specializes in heavy gauge thermoforming—also known as thick sheet vacuum forming—offering durable, high-quality plastic parts for demanding applications. We focus on custom solutions using advanced forming techniques, supported by in-house tooling, CNC trimming, drilling, and full secondary operations. With end-to-end capabilities, ForTOP delivers precision-formed components tailored for retail display, industrial, and commercial use.

Heavy Gauge Thermoforming

ForTOP specializes in heavy gauge thermoforming—also known as thick sheet vacuum forming—offering durable, high-quality plastic parts for demanding applications. We focus on custom solutions using advanced forming techniques, supported by in-house tooling, CNC trimming, drilling, and full secondary operations. With end-to-end capabilities, ForTOP delivers precision-formed components tailored for retail display, industrial, and commercial use.

Custom Thermoforming Service We Provide

Design For Manufacturing

Thermoforming Tooling

Heavy Gauge Thermoforming

CNC Machining

Secondary Processes

Full-Process Tracking Service

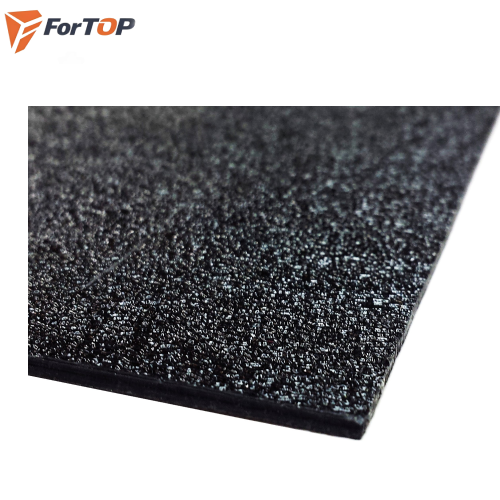

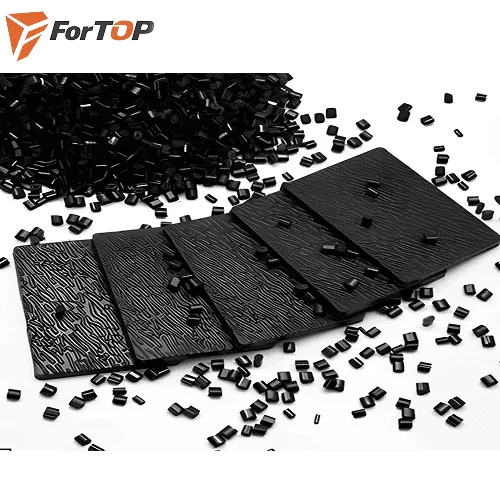

Optional materials

To Meet Your Heavy Gauge Thermoforming Needs,We Work With a Wide Range Of Materials including ABS/PMMA/HIPS/PET-G/ASA/PC…

What We've Made — and What We Can Make for You

The samples shown here represent just a small portion of our capabilities.

The samples shown here represent just a small portion of our capabilities.

Customize Your Vacuum Formed Parts

Fully Customizable

Make Your Idea Into Reality

- STEP 1: Initial Consultation we discuss your needs and study your 2D/3D drawings.

- STEP 2: Design Evaluation we analyze the files and proposes the best solution

- STEP 3: 3D Model Confirmation we finalize the 3D model with your approval.

- STEP 4: Mold & Jigs fabrication In-house mold & jigs fabrication begins.

- STEP 5: Sample Production We create and confirm prototypes with you.

- STEP 6: Production Tooling Mass production molds are prepared.

- STEP 7: Trial Run We test and approve pre-production samples.

- STEP 8: Mass Production Complete manufacturing, finishing, assembly,

Customize Your Vacuum Formed Parts

Fully Customizable

Make Your Idea Into Reality

- STEP 1: Initial Consultation we discuss your needs and review your 2D/3D drawings.

- STEP 2: Design Evaluation we analyze the files and proposes the best solution

- STEP 3: 3D Model Confirmation we finalize the 3D model with your approval.

- STEP 4: Mold & Jigs fabrication In-house mold & jigs fabrication begins.

- STEP 5: Sample Production We create and confirm prototypes with you.

- STEP 6: Production Tooling Mass production molds are prepared.

- STEP 7: Trial Run We test and approve pre-production samples.

- STEP 8: Mass Production Complete manufacturing, finishing, assembly,

Advantages of Heavy Gauge thermoforming

(also known as thick sheet vacuum forming)

More cost-effective for smaller volume runs

The price advantage comes from two key benefits of thermoforming: 1) Lower tooling costs, and 2) Flexible tooling and molding setups that make design changes quicker and less labor-intensive.

durable and high quality

Thermoformed products are built to last—unlike metal, they won’t rust, and unlike fiberglass, they won’t crack. They're strong, durable, and made for long-term performance.

Quicker Lead Time

Thermoforming offers much faster lead times and prototyping compared to injection molding. Plus,our in-house facilities allow for greater control over quality and efficiency.

Lower Tooling Cost

Thermoforming uses lower pressure, which means lower tooling costs and simpler equipment. This reduces upfront investment for prototyping and product development. Plus, with our in-house tooling shop, we speed up the entire process.

Lightweight products increase sustainability and efficiency

Lighter than metal, more efficient than fiberglass — our thermoformed parts help cut down logistics costs and improve handling efficiency.

Small or large products are possible

With the possibility to create sheets of varied sizes and countless different molds, thermoforming can create parts big or small.

What Makes Us the Right Partner

- Cut out the middleman and save up to 20%—all while maintaining top-tier quality.

-

- In-house tooling, advanced equipment, and decades of expertise ensure quick samples(with 2 weeks) and fast production(3-5weeks) you can count on.

-

- Your one-stop solution for thermoformed parts and all matching machined components — thanks to our full range of in-house equipment including 3-Axis & 5-Axis CNC.

-

- Factory-Direct Pricing

- Rapid Samples with Dedicated In-House Team

- In-House tooling Shop — Faster Turnaround, Full Control

- Responsive Sales & Support Team

What Makes Us the Right Partner

- Cut out the middleman and save up to 20%—all while maintaining top-tier quality.

-

- In-house tooling, advanced equipment, and decades of expertise ensure quick samples(with 2 weeks) and fast production(3-5weeks) you can count on.

-

- Your one-stop solution for thermoformed parts and all matching machined components — thanks to our full range of in-house equipment including 3-Axis & 5-Axis CNC.

-

- Factory-Direct Pricing

- Rapid Samples with Dedicated In-House Team

- In-House Tooling Shop — Faster Turnaround, Full Control

- Responsive Sales & Support Team

WHO ARE WE

About ForTOP

Founded in 2001 and based in Guangdong,China. Fortop Manufacturing Co., Ltd. is a trusted manufacturer specializing in custom heavy-gauge thermoforming. With over 24 years of experience and a 3,000 m² facility equipped with 3-Axis and 5-Axis CNC Machining Centers, in-house tooling, and multiple forming lines, we deliver high-quality plastic parts tailored to the unique needs of global clients.

Our thermoformed products are widely used in retail displays, equipment guards, device enclosures, the planting & cultivation industry, and infrastructure engineering. We proudly support end users like Walmart, Target and Sephora, and provide custom heavy gauge thermoforming parts with complete secondary services for equipment OEMs, medical device manufacturers, and government projects.

Over 70% of our output is exported to the U.S.. We’re ready to work with you — as your trusted, responsive, and long-term partner in custom heavy gauge thermoforming. Let’s build something great—together!

WHO ARE WE

About ForTOP

Founded in 2001 and based in Guangdong,China. Fortop Manufacturing Co., Ltd. is a trusted manufacturer specializing in custom heavy-gauge thermoforming. With over 24 years of experience and a 3,000 m² facility equipped with 3-Axis and 5-Axis CNC Machining Centers, in-house tooling, and multiple forming lines, we deliver high-quality plastic parts tailored to the unique needs of global clients.

Our thermoformed products are widely used in retail displays, equipment guards, device enclosures, the planting & cultivation industry, and infrastructure engineering. We proudly support end users like Walmart, Target and Sephora, and provide custom heavy gauge thermoforming parts with complete secondary services for equipment OEMs, medical device manufacturers, and government projects.

Over 70% of our output is exported to the U.S.. We’re ready to work with you — as your trusted, responsive, and long-term partner in custom heavy gauge thermoforming. Let’s build something great—together!

OUR TEAM

Teamwork Makes the Dream Work

Meet the core team behind your project — from engineering to customer support, we work together to deliver excellence.

- General Manager

- Gu Zai

- Combining strategic vision with hands-on leadership to deliver high-quality custom thermoforming solutions worldwide.

- Sales Manger Shirley Fu

- Driving customer success with tailored solutions, responsive service, and a deep understanding of custom needs.

- Account Manager

- Michelle Yang

- Ensuring smooth communication, fast responses, and seamless project coordination from inquiry to delivery.

- Head of MFG

- Leo Yuan

- Overseeing day-to-day production with a focus on quality, efficiency & delivery timelines,with 25-year industry experience.

- Chief Engineer

- Dave Zhang

- Turning ideas into Reality with speed, accuracy, and 15-year experience.

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our services, you can send an inquiry to contact us.

Thermoforming offers great versatility for product design and works well with several materials. The material used for a thermoforming project will be determined by the product’s intended use and additional industry-specific regulatory considerations. We mainly focus on ABS/PMMA/HIPS/PET-G/PC/Acrylic……

Absolutely! You can choose the size, type of plastics materials, and even the color and surface texture. Just send us your drawing for checking first.

No worries — our engineering team will review your design and recommend the most suitable material based on your product’s application, strength requirements, and budget. We’ll also evaluate the feasibility and suggest improvements if needed, ensuring your project is both practical and cost-effective.

Our typical lead time is 2–5 weeks, depending on the complexity of the project and order volume. For urgent needs, we also offer expedited services — just let us know your timeline!

Yes — we’re built for it. Small batch prototyping is one of our strengths. It helps you move faster, test smarter, and reduce risk before scaling up.

We typically produce prototypes within 2 weeks, depending on the complexity and material requirements. With our in-house mold shop and rapid tooling capabilities, we help you validate your concept quickly and efficiently.

No risks, just results.

We back every project with a

full refund guarantee.

Backed by in-house capabilities, hands-on experience, and a commitment to your deadlines and goals.

Phone: +86 18925329050

info@fortopmade.com

sales@fortopmade.com

No risks, just results. We back every project with a full refund guarantee.

Backed by in-house capabilities, hands-on experience, and a commitment to your deadlines and goals.

Phone: +86 18925329050

info@fortopmade.com

sales@fortopmade.com